No products in the basket.

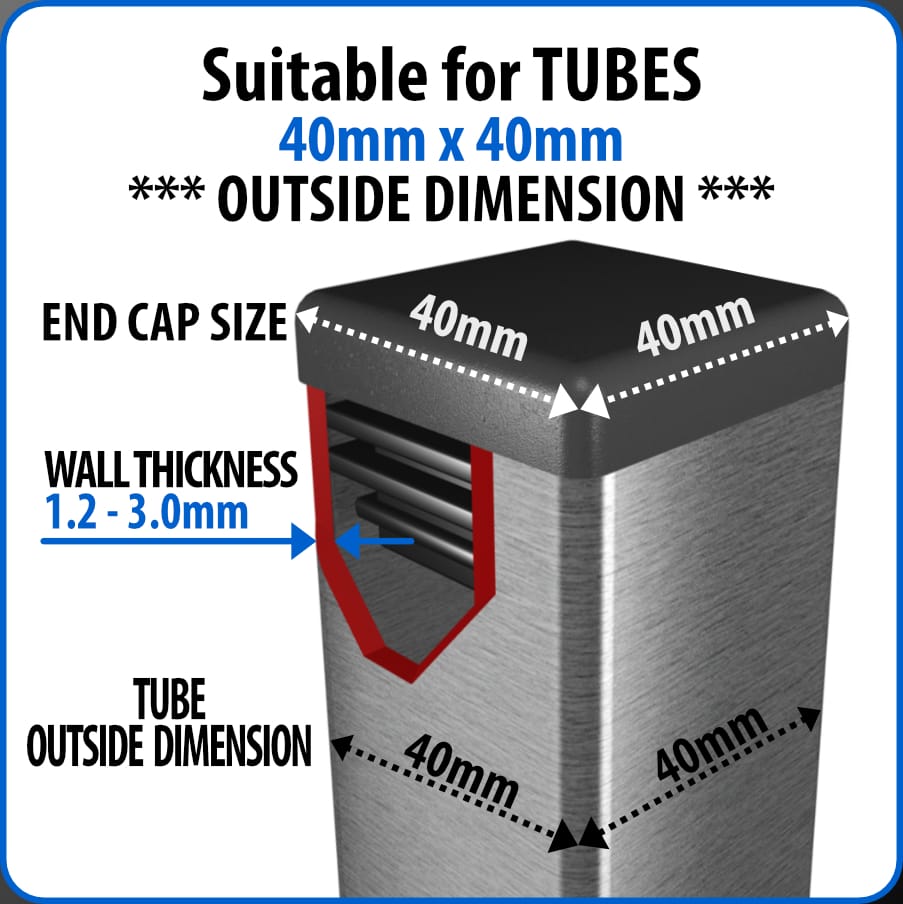

Measure the ***OUTSIDE DIMENSION*** of the TUBE, as shown in the picture below. ***NOT INSIDE***

If you don’t have a calliper, don’t worry, you can also measure with a ruler or a metal tape.

When measuring with a metal tape, measure from the line at 10cm, as measuring from the metal head you may get an error of +/- 2mm

Next, you need to measure the wall thickness.

Each end cap has a different wall thickness it will fit on, sometimes there may be two or even three end caps with a different wall thickness for one size.

When measuring with a metal tape or ruler, you need to measure the dimension from the outside and inside.

Then subtract the outer dimension from the inside dimension and divide by two, this will be your wall thickness.

For example, the external profile dimension is 25mm and the internal dimension is 23mm.

You need to subtract 25mm from 23mm which is 2mm and divide by two which is 1.0mm the wall thickness of your profile.

We also have a video in which we show step by step how to properly match the end cap to the profile.

What happens if you don’t follow our instructions and measure the dimension inside?

The plug will be the size of your hole as pictured below

All over the world, end caps are measured the same way, which is outside dimension plus wall thickness.

Each profile has a different wall thickness and the end cap must perfectly match the external dimension of the profile, which is why the most important dimension for end caps is the external dimension plus wall thickness.

Thank you for taking the time to read the instructions