No products in the basket.

Learning how to measure for plastic end caps correctly is the secret to a professional, secure fit that lasts. It can seem complicated, but it all comes down to two simple measurements. Getting them wrong leads to frustration, but getting them right is easy when you know how. This definitive guide will walk you through the exact steps to ensure you order the correct end cap, every single time.

There’s nothing more frustrating than your online order arriving, only to discover the parts don’t fit. When it comes to plastic end caps, a few millimetres can make all the difference between a professional, secure finish and a cap that’s either too tight to fit or too loose to stay in place.

As a specialist UK supplier, we’ve helped thousands of customers find the right part. To save you time, money, and frustration, we’ve created this definitive guide. Follow these steps to ensure you order the correct end cap, every single time.

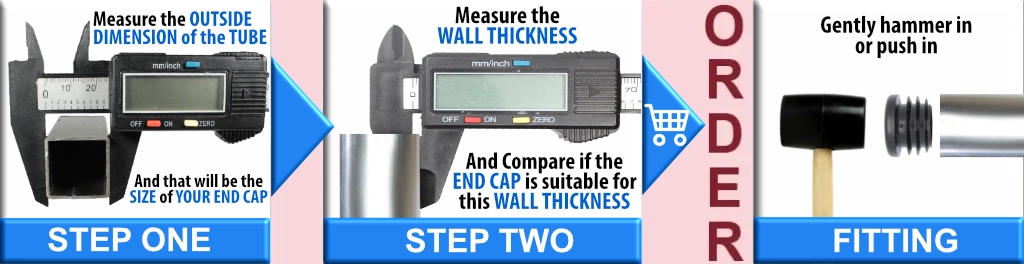

Forget the guesswork. Choosing the right end cap all comes down to two simple measurements:

Let’s break them down.

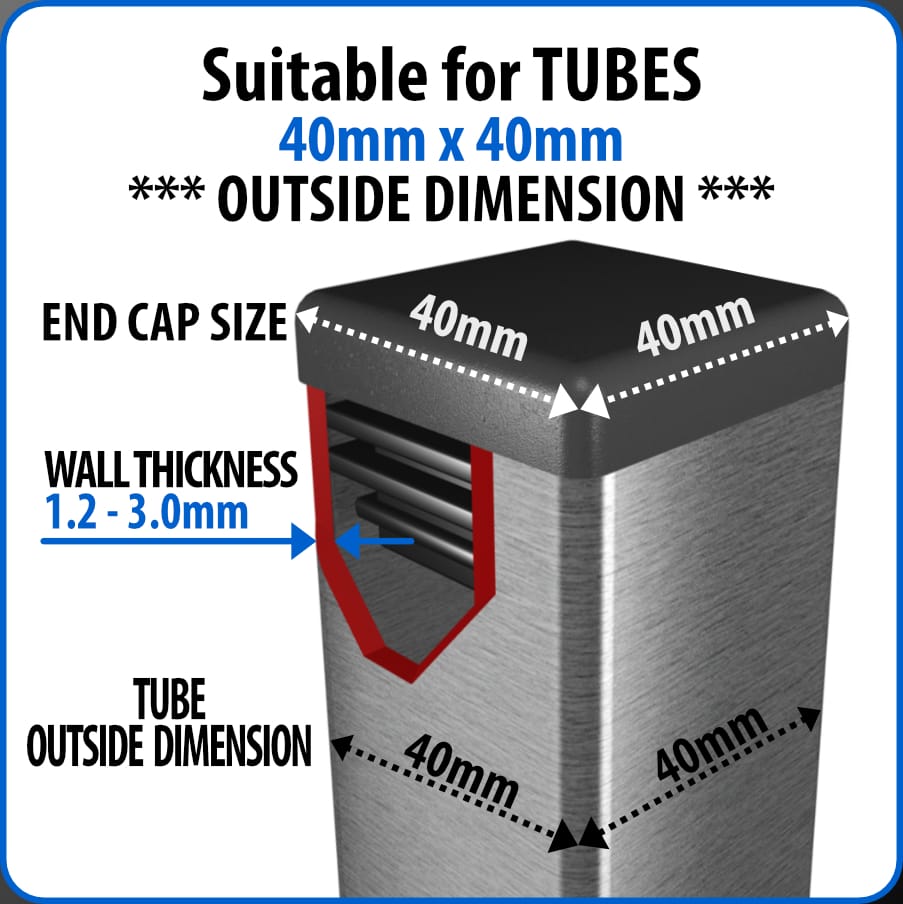

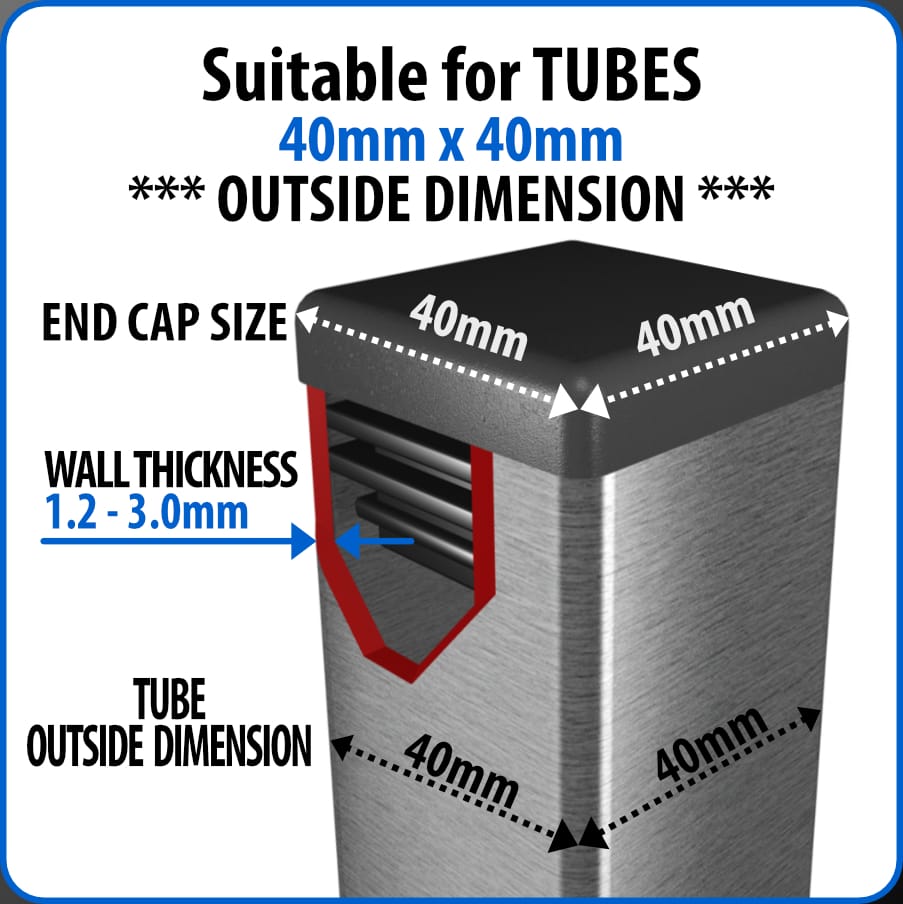

This is the most important measurement, as it determines the size of the cap you need.

Why? The head of the end cap is designed to sit flush with the outer walls of your tube, giving it a clean, professional look.

This is where most mistakes happen. The outside dimension tells you which size cap to look for, but the wall thickness tells you if that cap will actually fit. The flexible ribs on an end cap are designed to grip the inside of the tube, and every cap has a specific range of wall thicknesses it can accommodate.

1. Direct Measurement (Best Method): Use a digital caliper to measure the thickness of the tube wall directly. This is the most accurate way.

2. The Calculation Method: If you can’t measure the wall directly, use this simple formula:

For the most accurate results, a digital (or vernier) caliper is always the best tool. However, a tape measure can work if you follow one simple rule:

The 10cm Trick:

Never start your measurement from the loose, wobbly metal hook at the end of a tape measure. This hook has intentional ‘play’ that can cause an error of 1-2mm. For a precise reading, align the 10cm mark with the edge of your tube, take the final reading, and then simply subtract 10cm. For example, if your measurement reads 14.5cm, your actual dimension is 4.5cm (45mm).

Now that you have your accurate wall thickness, check the product description on our website. For example, our standard 40x40mm end cap is designed for a wall thickness range of 1.2mm to 3.0mm.

If your measured wall thickness is 2mm, it falls perfectly within this range. You’ve found your match!

Problem 1: “My cap is too tight! It must be a cheap fake.” This is a common issue with heavy-duty profiles. You’ve correctly measured your 40x40mm tube, but the wall thickness is 4.0mm. A standard cap (range 1.2-3.0mm) will not fit. This is why we stock heavy-duty end caps for thicker walls. Our other 40x40mm cap, for example, is designed for a 3.0mm to 5.0mm wall, which would be the perfect choice. Always check the range!

Problem 2: “My cap is too small! It must have shrunk in the post.” This happens when customers skip Step 1 and measure the inside hole of their tube. They then order a cap that matches the hole size, which is, of course, far too small to fit over the outside of the tube. Remember: Always measure the OUTSIDE of your tube to determine the cap size.

By following these simple steps, you can be confident that you’re ordering the right part for the job.

If you’re ever in doubt, just get in touch. We’re based right here in the UK and are always happy to help you find the perfect fit.